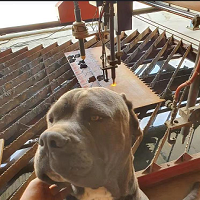

Common Trouble in cnc cutting machines

--By CNC CUTTER LIMITED

I. External fault

Due to the increasing reliability of modern CNC systems, the failure rate is getting lower and lower, and few failures occur. Most of the failures are non-system failures and are caused by external causes.

II. NC system failure

The external fault of the CNC cutting machine can be divided into soft fault and hard fault caused by external hardware damage.

(i) Hardware failure: Sometimes due to the NC system hardware damage, make the machine down. For the diagnosis of such faults, we must first understand the working principle of the numerical control system and the function of each circuit board, and then analyze according to the fault phenomenon, and use the exchange method to accurately locate the fault point under conditions.

(ii) Software failure: Some failures are caused by NC system parameters, sometimes due to improper settings, sometimes due to accidental changes or confusion of parameters, such failures as long as the adjustment of parameters, will naturally disappear. There are also some failures due to accidental reasons to the NC system in a dead cycle state, such failures sometimes must be forced to start the method to restore the use of the system.

Sometimes the diagnostic process is complex, but once the problem is identified, it is easier to solve. External troubleshooting should follow two principles. First of all, master the working principle and action sequence of CNC cutting machine. Second, PLC ladders should be used.

NC system status display function or off-camera programmer monitoring PLC operation status, generally as long as the above principles, careful, general numerical control cutting machine failure will be timely to eliminate.

III.the failure of the servo system

Because the control core of the numerical control system is the digital control of the feed part of the cutting machine, and the feed is controlled by the servo unit servo motor, driving the ball screw to achieve, by the rotary encoder to do the position feedback element, forming a semi-closed loop position control system. Therefore, the role of servo system in CNC machine tools is quite important. The failure of the servo system is generally caused by problems such as servo control unit, servo motor, speed measurement motor, encoder, etc.

CNC cutting machine because of the working environment is very poor, most of the failure is caused by external reasons, in the case of failure, can not be blindly dismantled, to avoid the expansion of the fault. Usually to observe more, record the machine when the normal operating status of the indicated data. As long as we usually accumulate more, scientific analysis at work, we can ensure the normal work of CNC cutting machine.

CNC CUTTER gas cnc cutting and stripe cutting machine