What are the maintenance methods of the plasma cutting machine?

--By CNC CUTTER LIMITED

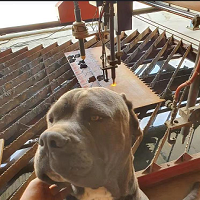

Plasma cutting machine we all use frequently, donot mean no care after buy, in the process of use need to often maintain the plasma cutting machine, only in this way cnc plasma cutting machine can be used for a longer period, in order to be more durable. So usually how we are on the plasma cutting machine which parts need maintenance?

1. Rail racks, to often check the rail racks to see there is no residual iron slag, there must be iron slag must be cleaned up in time, otherwise the iron slag will affect the operation of the plasma cutting machine, affect cutting accuracy, iron slag is also easy to enter the slider, when the slider inside the steel beads will fall off, so that not only affect the effect, It also causes damage to the slider, which needs to be replaced, increasing the cost. Also in time to the rail rackoiled to prevent rust.

2. cutting torch and consumables, to always check the connection thread of the cutting gun, replace the consumables, be sure to put on clean paper or cloth.

3. Cut nozzle to be often cleaned or replaced, if the cut mouth damage is not serious, you can wipe the oxide deposited inside, if the cut mouth direct damage is more serious, it is recommended to directly replace a new set of mouth cuts and electrodes, to avoid affecting the effect of cutting.