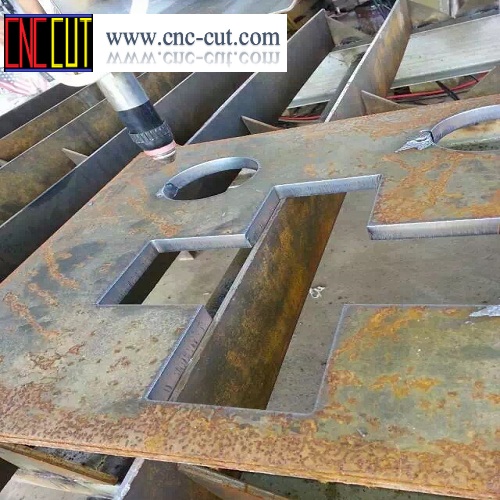

Ways to improve the life of plasma cutting tips / NozzlWays to improve the life of plasma cutting tipss/ consumables By CNC CUTTER LIMITED.

HI, My Friends, Welcome selected CNC plasma and oxyfuel cutting machines from CNC CUTTER LIMITED, after a certain period using, you may consider how to prolong the life time of plasma cutting nozzles, here it is:

- To ensure that the plasma generator correct air pressure and flow.

The correct pressure and flow of plasma is very important for the service life of the consuming parts. If the air pressure is too high, the life of the electrode will be greatly reduced; If the air pressure is too low, the life of the nozzle will be affected. When you purchase plasma generator and CNC machine from we CNC CUTTER LIMITED together, please check the recommendation table.

- The use of reasonable cutting distance

In accordance with the requirements of the instruction manual, the use of reasonable cutting distance, cutting distance is the distance between the cutting nozzle and the surface of the work piece, when perforated, try to use the normal cutting distance of 2 times the distance or the maximum height that can be transmitted by the plasma arc. CNC Cutter Limited manufacturer recommend 5-10mm normally.

- Perforation thickness should be within the permitted range of the machine system

The cutter cannot be perforated on a steel plate that exceeds the working thickness, and the usual perforation thickness is 1/2 of the normal cutting thickness.

Nozzle do not overload use

Overloading the nozzle (i.e. exceeding the working current of the nozzle) can quickly damage the nozzle. The current strength should be 95% of the working current of the nozzle. For example, the current strength of the nozzle at 100A should be set to 95A.

- Keep the plasma gas dry and clean

Plasma systems require dry and clean plasma gases to function properly. Dirty gases are usually problems with gas compression systems, which shorten the life of the consumables and cause abnormal damage. The gas mass is tested by locating the torch in the test state, placeing a mirror under it, consuming the gas inside the torch, and if water and mist appear on the mirror, the cause needs to be identified and corrected. This point often ignored by users, CNC CUTTER LIMITED notice you, dry and clean air is very important for prolonging regular cutting lifetime.

- Cutting start from the edge

Cut from the edges as much as possible, not perforated. Using edges as the starting point extends the life of the consumables, and the correct approach is to point the nozzle directly at the edge of the work piece before starting the plasma arc.

- Avoid plasma arc lengthing expansion

If the plasma arc can only reach the surface of the work piece by elongation and expansion, this stretch and expansion occurs at both the beginning and end of the cutting, which can cause abnormal damage to the nozzle. This problem can be avoided if the correct edge starting point technique is used and the appropriate "arc breaking" signal time is chosen.

- Reduce unnecessary "arcing time"

The consumption of nozzles and electrodes is very fast at the start of the arc, and the torch should be placed within the cutting metal walking distance before starting.

- Apply anti-splash chemical coating on the protective shell

Splash-resistant chemical coatings help reduce slag accumulation on the protective case. However, be sure to remove the protective case from the torch before applying splash-proof paint.

- Remove the slag from the protective case

The slag on the torch case should be removed frequently, otherwise it will cause a destructive heavy plasma arc.

- Remove the gas after replacing the consumables

After replacing the consumables or after a long shutdown, remove the gas (2-3 minutes is appropriate) to ensure that water and mist are removed from the torch.

- Keep the torch and consumables as clean as possible

Any dirt on torches and consumables can greatly affect the function of the plasma system. When replacing the consumables, place them on a clean velvet cloth, check the torch's connection threads frequently, and clean the electrode contact surfaces and nozzles with hydrogen peroxide cleaners.

- Remove oxides from air or oxygen nozzles

When air or oxygen plasma is used, oxides are deposited in the nozzle, which affects airflow and reduces the life of the consuming parts. Wipe the inside of the nozzle with a clean velvet cloth to remove oxides.

- The use of softened water into the torch

Hard water causes precipitated metal impurities on the nozzle ring, which affects airflow, reduces torch quality and shortens the life of the consumables.

- Check the air and cooling flow daily

One of the most common causes of torch damage is the lack of cooling flow, which requires frequent inspection of the torch's airflow and air pressure (e.g. air-cooled) or coolant (e.g. water-cooled), and if air flow is found to be insufficient or leaking, immediately stop to troubleshoot.

Over.