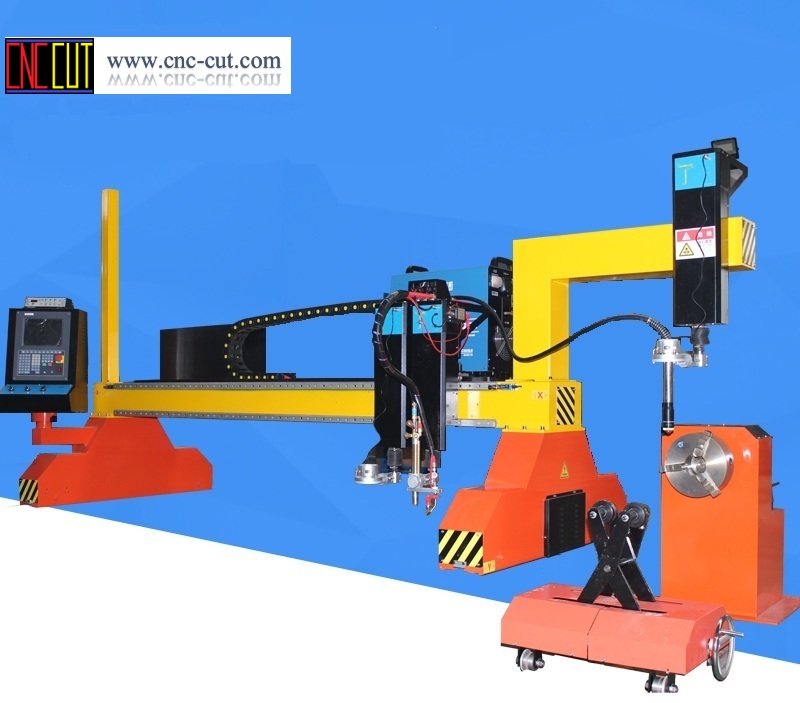

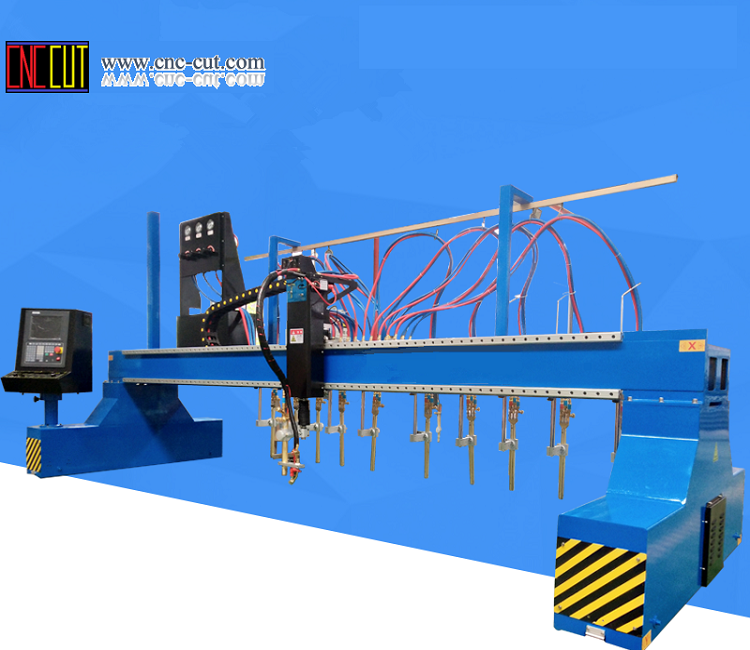

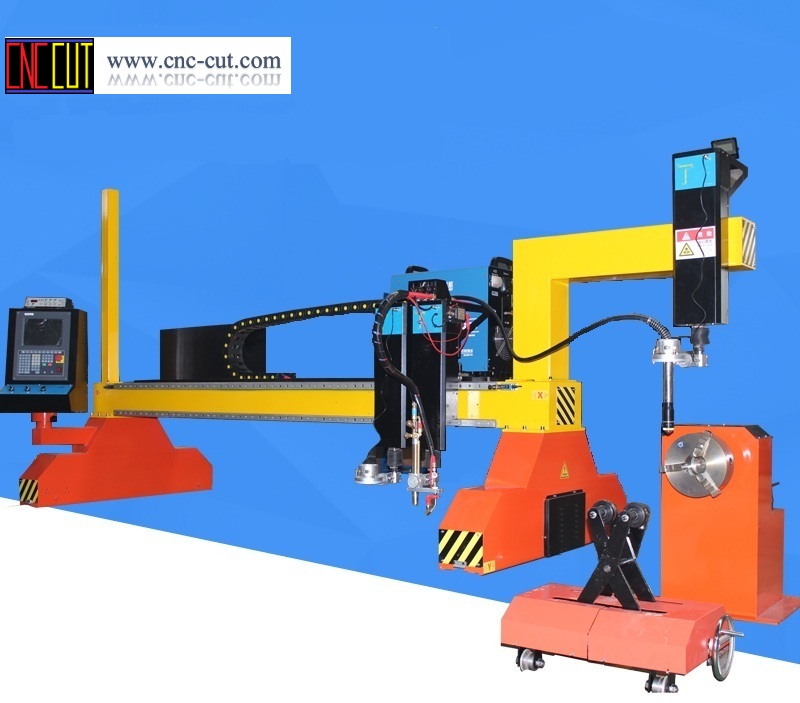

sheet and tube plasma cutting machine

CCL-GT

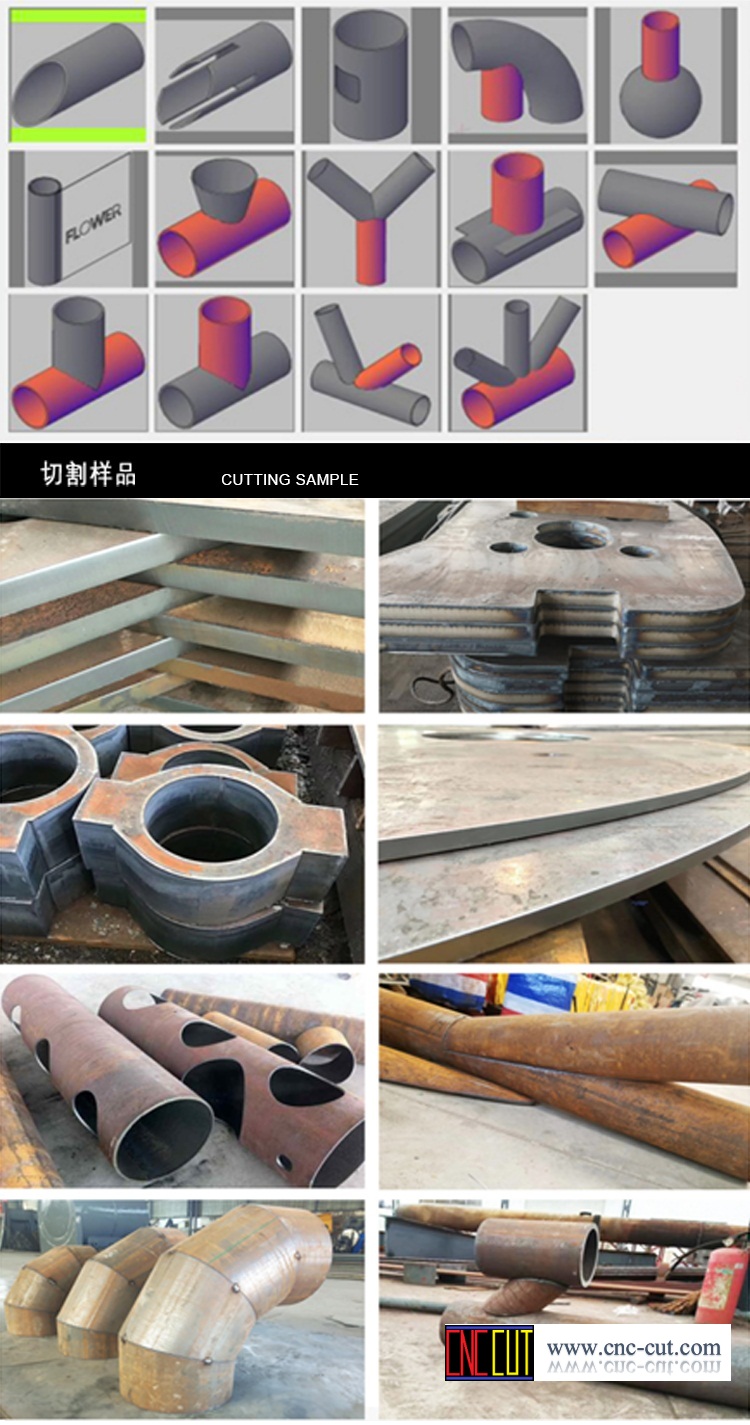

1.Suitable for metal sheet and pipe cutting both. 2.Plasma and or flame cutting. 3.Sheet cutting area: 2.0m*4.0m, 3.0m*6.0m, 4m*8.0m et; pipe cutting diameter 30mm-300mm, 60mm-600mm.

Parameter

|

|

Item |

Unit |

Parameter |

|

1 |

Rails center distance |

mm |

3000-7000(Customized available) |

|

2 |

Rail length |

mm |

8000(Customized available) |

|

3 |

Effective cutting width |

mm |

Rails center distance-800mm |

|

4 |

Effective cutting length |

mm |

Rail length-2000mm |

|

5 |

Pipe diameter |

mm |

30-300mm; 60-600mm |

|

6 |

Pipe length |

mm |

Rail length-2000mm |

|

7 |

Cutting Speed |

mm/min |

0-6500 |

|

8 |

Empty moving speed |

mm/min |

0-10000 |

|

9 |

Cutting thickness |

mm |

Plasma: 0.1-75mm Mild steel, stainless steel, Aluminium, copper etc Flame: 6-300mm mild and medium steel. |

Our advantage compared with the other suppliers:

- Adopts the box welding structure, material uses 8mm national standard steel plate after laser cutting;

- The frame used the bending machine to break into 90 degrees arc, greatly increase the whole machine beam rigidity, lengthens the service life.

- The whole machine is by heat treatment to eliminate stress, with good rigidity, not deformation, high precision, light weight, small inertia characteristics.

- Longitudinal frame two ends are equipped with a horizontal guide wheel, which can adjust the clamping degree of the eccentric on the bottom of the drive frame, so as to keep the whole machine in a stable direction in the movement.

- Equipped with track dust collectors, at any time to scrape debris accumulated on the guide surface.

- Longitudinal and transverse drive all have precision gear rack to drive.

- Cross guide rail using precision cold-drawn guide plate, longitudinal guide is train rail-type rail through the precision processing.

- International famous precision gear reducer, Servo motor, valves, hose etc, to ensure cutting quality and long life time.